Process Safety

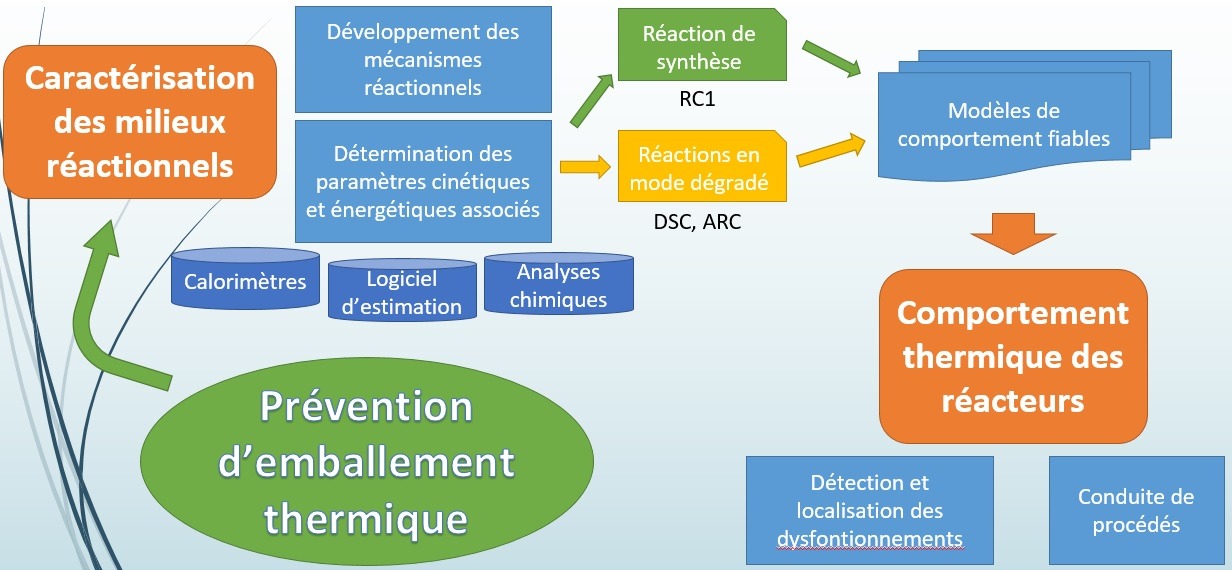

lIndustrial safety is a major focus for the Normandy region, with a dense and diversified industrial fabric (nuclear energy, gas, chemicals, storage of hazardous materials) and companies classified as SEVESO. Among the main causes of accidents, thermal runaway of reaction masses is one of the most common; the tools and methods for predicting and characterising it are still being researched. Understanding the phenomena involved in this type of accident, which remains fairly difficult given the wide variety of substances and chemical reactions involved, enables us to better characterise the reaction media and assess the margin of confidence in the event of malfunctions.

Preventing runaway requires, on the one hand, a study of the thermokinetics of chemical syntheses in normal and degraded mode, which is essential for calculating the safety parameters of chemical processes: the temperature for which the runaway time is 24 h in adiabatic conditions (TD24) or the temperature rise of the reaction medium in adiabatic mode (ΔTad) or the time available until the maximum reaction speed (TMRad). It is also necessary to study the dynamic behaviour of chemical reactors.